Rectangular Sight Glass

For viewing the internals of pipelines, containers, pressure ves-

sels, reactors, silos etc. used principally as a liquid level indicator

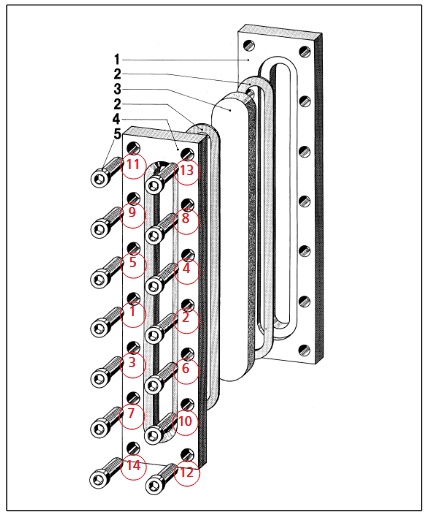

The base flange of the sight glass unit is welded into or onto the

vessel wall; the glass plate with gasket either side is firmly held in

place by bolted on cover flange.

Applications

Pressure 16 bar

Pressure 16 bar

Vacuum

Vacuum

NB: Before putting the fitting into operation, the strength of

the cutout reinforcement in combination with the vessel wall

should be checked in accordance with TÜV leaflet.

NB: Before putting the fitting into operation, the strength of

the cutout reinforcement in combination with the vessel wall

should be checked in accordance with TÜV leaflet.

Design Features

100°C when using sodalime glass, DIN 8903

100°C when using sodalime glass, DIN 8903

243°C when using borosilicate glass, DIN 7081

243°C when using borosilicate glass, DIN 7081

These temperatures refer to unprotected glass (i. e. without mica

protective sheet).

These temperatures refer to unprotected glass (i. e. without mica

protective sheet).

If required by customer, and against additional charge, testing

and certification can be provided to DIN EN 10204 3.1/3.2

If required by customer, and against additional charge, testing

and certification can be provided to DIN EN 10204 3.1/3.2

Technical Specifications

Base frame : carbon steel S235JR+N (RSt 37-2); stainless steel 1.4571, 316 Ti or alternative

Seal - KLINGERSil C-4400; Neoprene; PTFE or alternative

Sight glass plate : soda lime glass: thermally prestressed, DIN 8903, max 100°C - borosilicate glass: thermally prestressed, DIN 7081, max 243°C

Cover frame : steel S235JR+N (RSt 37-2); stainless steel 1.4571, 316 Ti or alternative.

Securing bolts : Carbon steel 8.8 or stainless steel A4