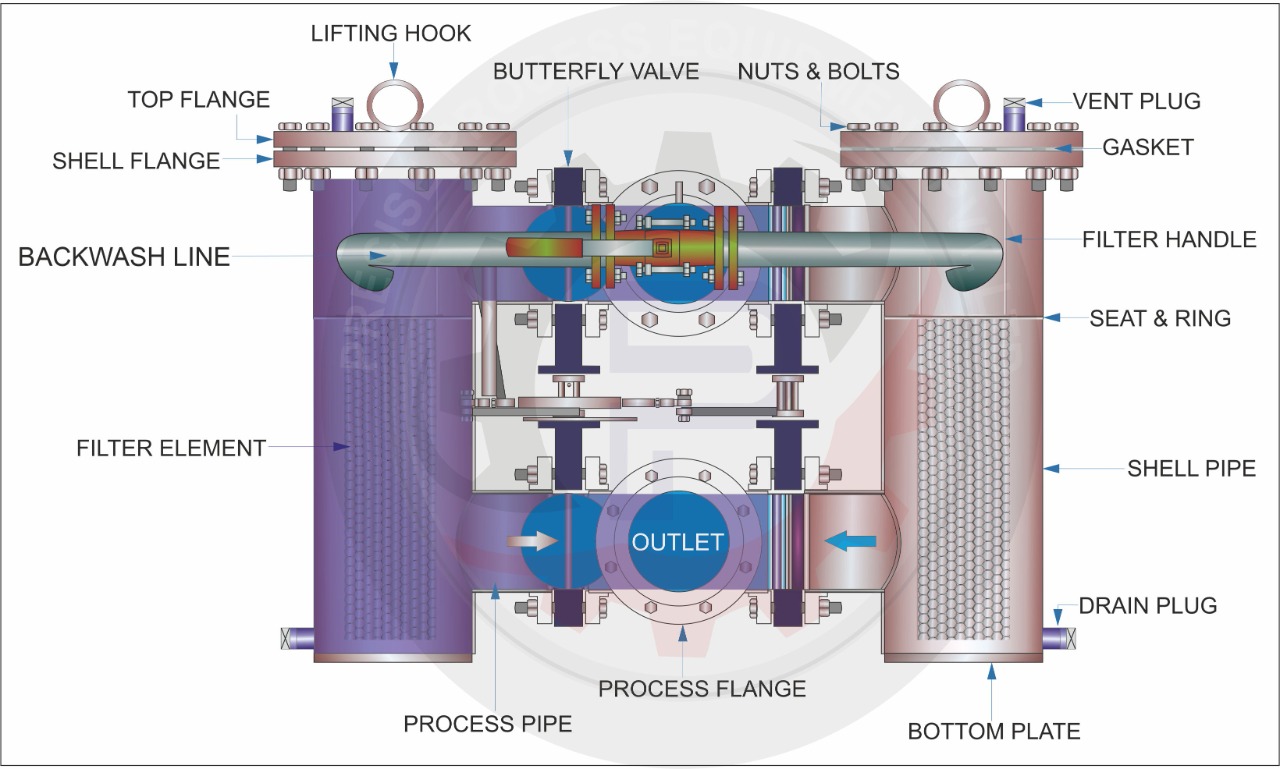

Duplex Strainer with backwash system

Duplex Strainers are designed where flow cannot be shutdown to service the strainer screen. Changeover is accomplished by use of butterfly valves

Differential pressure across the strainer should be measured regularly.

When basket is not clogged, pressure drop across basket is for example will be 0.18 bar.

During filtration basket starts to get clogged. When it gets clogged to 50%, then the pressure drop will become for example 0.25 bar.

At that point of time, the backwash valve should be manually opened & backwashing starts.

During this process drain valve of the filter should remain open.

During backwashing, flow will not get interrupted. Backwashing will go on till it completely cleans the basket. When differential pressure across basket reaches normal value the backwash valve should be manually closed along with the drain valve.

Backwashing also will stop.

Applications

Pump protection

Pump protection

Flow meter protection

Flow meter protection

Valve and regulator processes

Valve and regulator processes

Protection of heat exchanger and refrigerating set

Protection of heat exchanger and refrigerating set

Instrumentation and Piping item protection.

Instrumentation and Piping item protection.

Design Features

Can be installed in horizontal or vertical pipelines.

Can be installed in horizontal or vertical pipelines.

Drain connections are standard and are furnished with plug.

Drain connections are standard and are furnished with plug.

Perforated screen with 40 Mesh linings are standard.

Perforated screen with 40 Mesh linings are standard.

Other reining’s shall be done on request.

Other reining’s shall be done on request.

Vent valve can be provided with valve on request.

Vent valve can be provided with valve on request.

To meet high temperature and high pressure with suitable MOC and Sealing parts.

To meet high temperature and high pressure with suitable MOC and Sealing parts.

Technical Specifications

Materials of construction / Housing : Carbon Steel

Stainless steel in various grades, - other materials and coating available on request.

Filter Element : Carbon steel, Stainless steel in various grades - Other materials available on request.

End connection : Flanged [As per requested Table].

Sizes : are available from 1“ Line Size to 4”

Line size. Other / Higher sizes available on request.

Filtration Rating : Filtration rating available from 5 microns to 1000 micron

Pressure Rating : Up to 1000 PSI.High -pressure rating avail